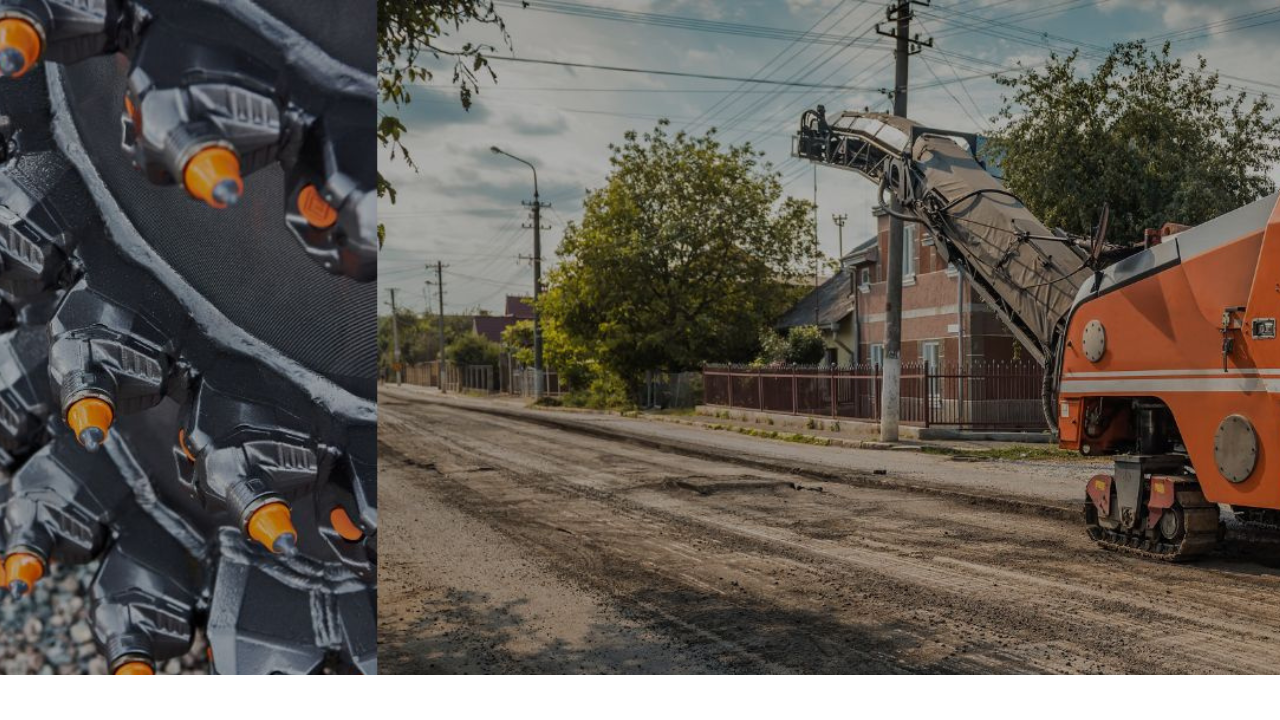

Road milling teeth serve as fundamental components for road construction. They enable the cutting of asphalt and concrete surfaces. The contact between abrasive materials shortens operational periods for road asphalt milling machine teeth and drives up total maintenance costs. Road milling teeth benefit from proper maintenance and strategic operation methods, which lead to longer operational periods and enhanced operational effectiveness.

Selecting High-Quality Milling Teeth

The selection of premium components stands as the initial measure to extend the operational life of road milling teeth. Consider the following factors:

- Tongue carbide combined with high-strength alloy steel creates milling teeth that resist wear effectively.

- The production method of teeth using modern forging methods combined with hard-facing technology helps them survive for extended periods.

- The teeth should match both the milling machine requirements and the intended application to stop premature wear.

Proper Machine Operation

The way operators handle their equipment directly determines how long milling teeth will last. To avoid unnecessary wear:

- The premature deterioration of components occurs when cutting speed exceeds optimal levels because it generates excessive heat and friction.

- The correct depth setting for cutting operations protects teeth from damage and prevents tooth chipping.

- The presence of excessive machine vibrations causes uneven wear and tooth breakage.

- Milling patterns that distribute wear evenly across all teeth will increase the total lifespan of the teeth.

Proper Cooling and Lubrication

Heat production plays a major role in the deterioration of milling teeth. To reduce heat-related damage:

- The installation of water spraying systems on machines enables proper water flow, which cools teeth while reducing overheating.

- Cooling lubricants should be used because they minimize both friction and heat accumulation.

- The practice of continuous milling should be interrupted by brief pauses to stop overheating.

Correct Storage and Handling

The correct storage methods, together with proper handling techniques, protect the components from unnecessary wear and damage. Best practices include:

- Placing the tool in a dry environment with low temperatures helps stop rust formation and corrosion development.

- A systematic arrangement of milling teeth prevents both accidental damage and tool misplacement.

- The proper handling method safeguards carbide tips from damage that could lead to chipping or breaking.

Investing in Advanced Wear-Resistant Coatings

Research in coating technology produces new methods to boost the extended operational lifespan of milling teeth. Some effective solutions include:

- Tungsten carbide coatings hold two key features: high resistance against wear combined with exceptional hardness.

- Hard-facing treatments provide two benefits: they enhance cutting edges and stop premature chipping.

- The implementation of nano-coatings enhances surface hardness and decreases friction. It results in extended operational performance.

Routine Inspection and Maintenance

The performance of tools and the avoidance of unexpected malfunctions depend on scheduled checks combined with regular maintenance practice. Important maintenance practices include:

- Each operation requires inspecting damage to check for blunt edges, cracks, and uneven wear patterns.

- The removal of dirt, along with debris and asphalt buildup from milling teeth, prevents both corrosion and deterioration.

- Operating a milling machine with damaged or excessively worn teeth leads to equipment strain, which reduces operational efficiency.

Conclusion

The longevity of road milling teeth depends on selecting premium materials together with correct machine operation, scheduled maintenance, proper cooling systems, and state-of-the-art coating solutions. Road milling operations become more efficient, while replacement costs decrease when contractors utilize these strategic methodologies for their milling tools.